Green Sort

Green Sort designs optical sorting and inspection systems used in post-harvest fruit and nut handling. Their technology is applied where consistent grading, defect detection, and throughput are critical to downstream quality and efficiency.

Green Sort systems are well suited for a defined range of crops, including blueberries, cranberries, apples, pears, cherry tomatoes, hazelnuts, and citrus crops such as oranges. These systems evaluate size, colour, and surface characteristics to support repeatable, objective sorting in commercial post-harvest environments.

We represent Green Sort because their approach aligns with how we believe fruit and nut crops should be evaluated after harvest — prioritizing consistency, accuracy, and practical integration over manual inspection alone.

What We Support

Green Sort systems support post-harvest inspection and sorting in commercial fruit and nut handling environments. These systems are used after harvest to evaluate product based on visual characteristics and to support grading, packing, and processing workflows.

We support Green Sort equipment where optical inspection improves consistency, repeatability, and efficiency, particularly in operations transitioning from manual sorting to objective, camera-based evaluation. Our focus is on practical integration into existing post-harvest lines rather than standalone or demonstration-only setups.

Target Crops

Green Sort optical sorting systems are used across a defined range of fruit and nut crops where post-harvest grading, defect detection, and consistency are critical.

Common applications include:

Blueberries

Cranberries

Apples

Pears

Cherry tomatoes

Hazelnuts

Citrus crops, including oranges

Crop suitability depends on product presentation, throughput requirements, and post-harvest line configuration. Systems are selected and configured based on how the crop is handled after harvest, rather than a one-size-fits-all approach.

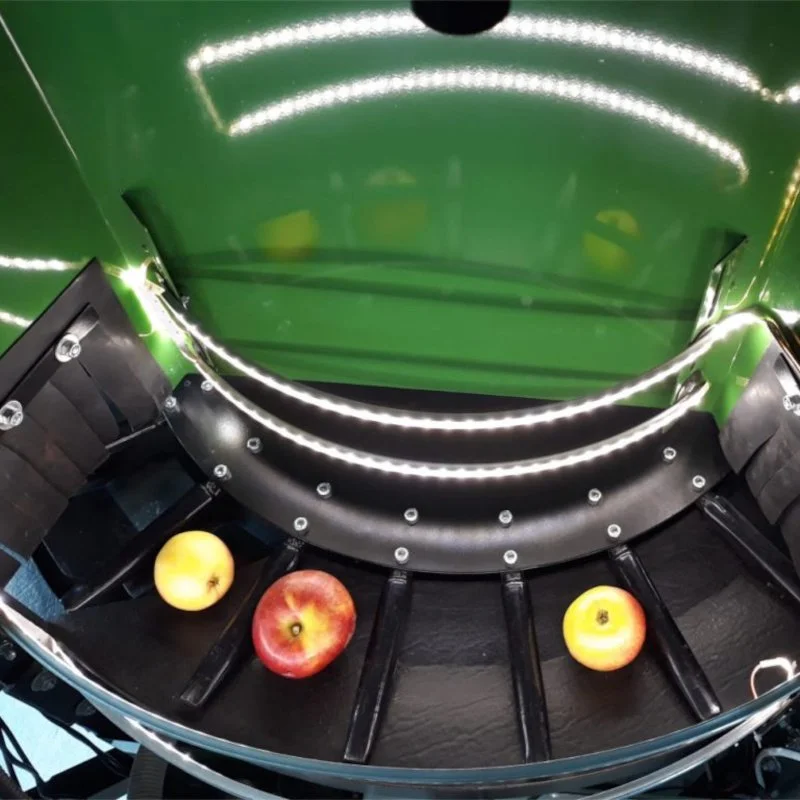

Optical Inspection & Defect Detection

Green Sort systems use camera-based optical inspection to evaluate individual fruit or nut units based on visual characteristics such as size, colour, and surface condition. This allows sorting decisions to be made consistently and repeatably across high-throughput post-harvest environments.

Inspection parameters are configurable to align with product specifications and quality objectives. Optical inspection is used where manual sorting alone becomes inconsistent, labour-intensive, or difficult to scale, particularly in operations requiring objective grading standards.

These systems are designed to support accuracy and repeatability within real processing lines, rather than laboratory or demonstration settings.

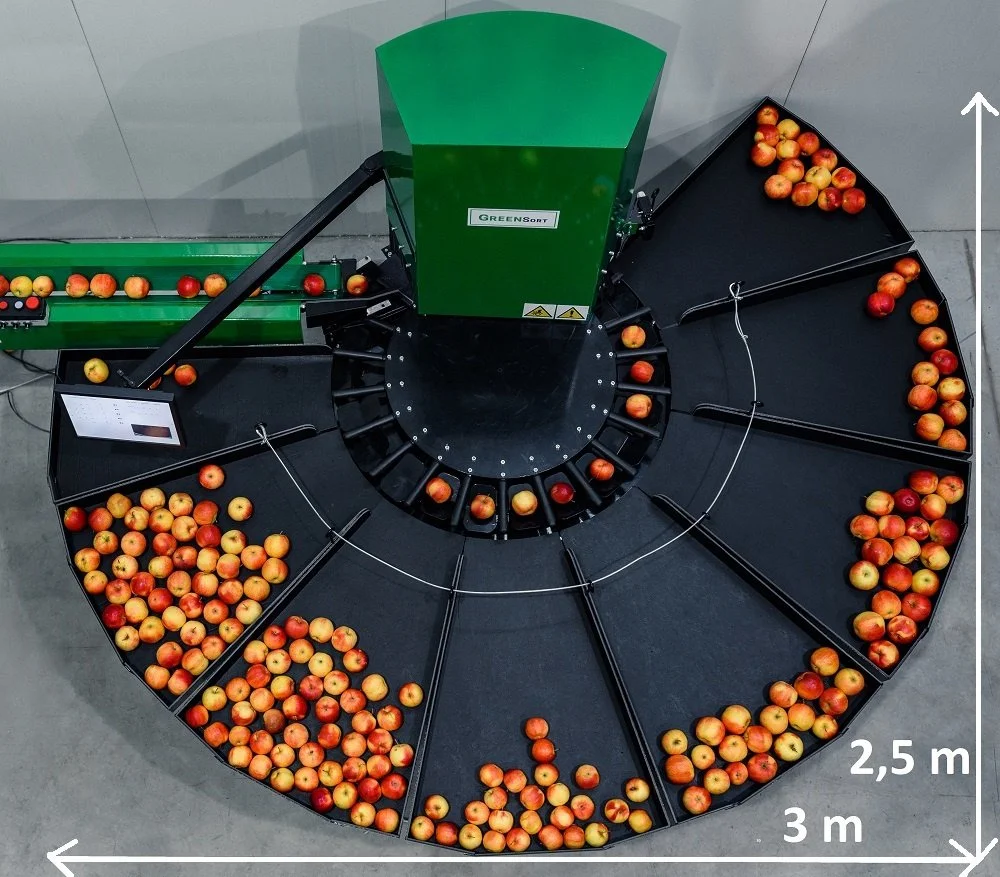

Post-Harvest Line Integration

Green Sort equipment is designed to integrate into existing post-harvest handling and processing lines. Systems can be configured to work alongside conveyors, material handling equipment, and downstream packing or processing stages.

Integration focuses on maintaining consistent flow, minimizing unnecessary handling, and supporting efficient movement from inspection to final use. System layout and configuration depend on facility design, crop type, and production objectives.

Our approach emphasizes practical integration within real production environments, ensuring optical sorting functions as part of a continuous process rather than a standalone step.

Who It’s For

Green Sort systems are well suited for operations where post-harvest consistency, throughput, and objective grading are required.

This equipment is typically used by:

Commercial fruit and nut growers

Packing and processing facilities

Operations handling high volumes or tight quality specifications

Producers transitioning from manual inspection to optical sorting

Green Sort systems are intended for environments where sorting is part of a broader post-harvest workflow, rather than small-scale or intermittent use.

Next Steps

If you have questions or would like to discuss suitability for your operation, please contact us.

For full technical specifications and system details, you can also visit Green Sort’s website.